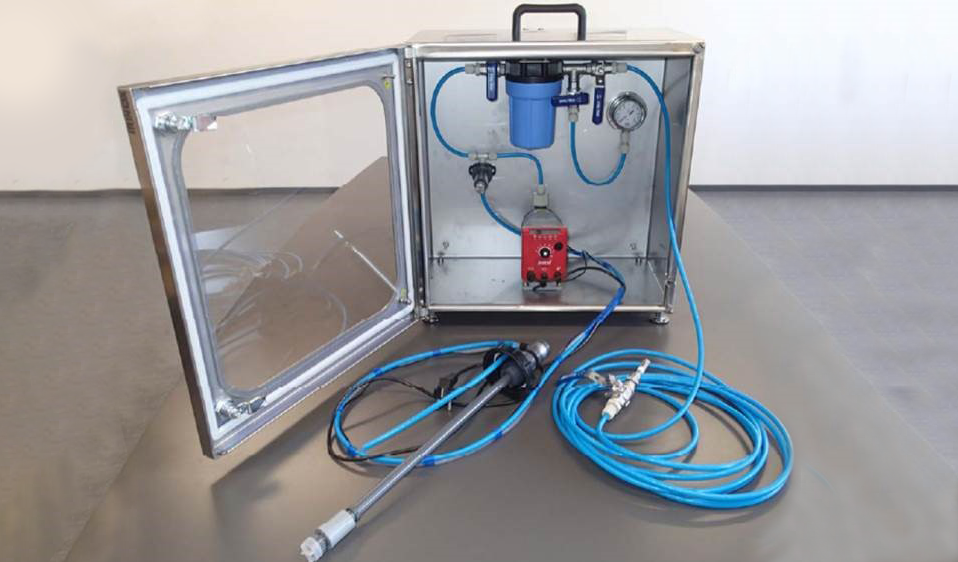

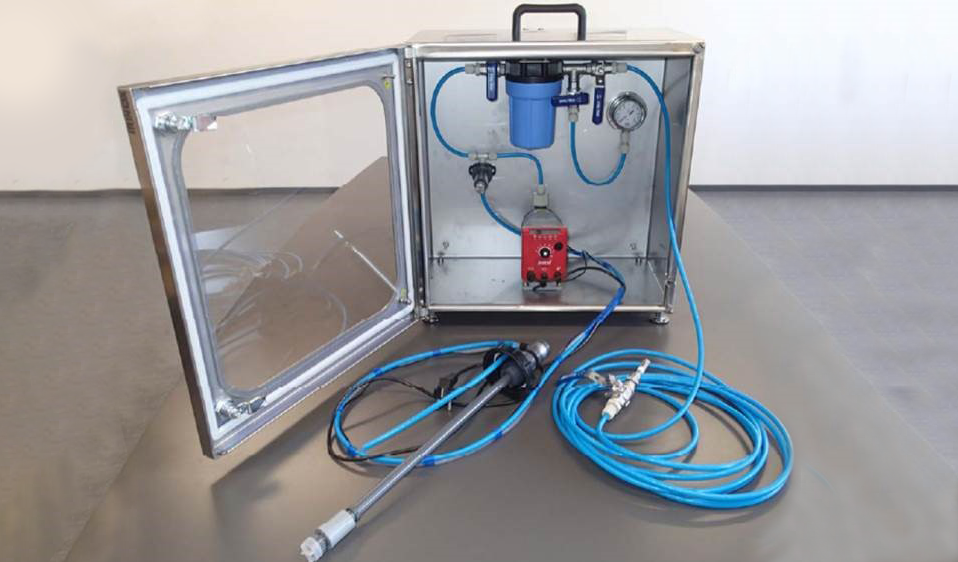

Surface Diffuser cleaning system

An efficient, simple, and cost-effective way to clean membrane diffusers

Rising head pressure due to sedimentation of mineral/biological scale on the membrane surface is a occurrence that every membrane diffuser system on the market is confronted with.

Whilst this problem is easy to ignore, eventually the head pressure will increase to a point where damage to your membrane diffuser is immanent resulting in two scenarios that are detrimental to the performance and general operation of the plant.

- An increased power demand due to extended aeration cycles

- Insufficient blower capacity to reach DO target.

Fortunately, Hydroflux offer an effective and simple to use portable chemical CIP unit to clean all types of membrane diffusers. This unit is designed to fumigate a suitable cleaning acid into the air piping system, helping to release scale built up on the membrane surface.

Main cabinet stainless steel cabinet

- High quality Prominent dosing pump – capable of pumping up to 7.5 L/hr

- Suction line with weight

- Dosing line with fumigating injection spray nozzle to suit ½” fitting.

- Pressure return line

- Filter unit with cartridge

- Isolation valves

- Complete instruction manuals

- 300 x 300 x 200 stainless steel cabinet, with handle for ease of mobility.

- 240V AC standard AU power socket. No other service connection required.

- Special fumigation injection spray nozzle to suit 1/2” fitting.

Hydroflux can manage the entire cleaning process, through provision of specialty labor and cleaning chemicals across ANZ.