Rental chemical dosing systems

Hydroflux Utilities understands that during the life of a project or operation, different challenges related to water/waste or odor will occur without warning. In these instances, its best to work with a company with over 400 years’ combined experience developed through building and operating more than 150 wastewater plants across Australia and Asia, providing first time solutions savings money and time.

Hydroflux stocks a number of different equipment solutions ready for immediate dispatch, covering the following common solutions;

- pH correction

- Dust suppression solutions

- Disinfection and bacterium control

- H2S and noxious odour solutions

- Polymer dosing for DAF’s, clarifiers, centrifuges and belt/screw and filter presses.

- Silt and dirty water management systems

- Diffuser membrane cleaning system

Your local Hydroflux engineer will provide extensive experience to your team, offering a chemical and equipment solution that provides the most thorough and targeted solutions best suited to manage your chemical dosing requirement in the most economical way. Call today

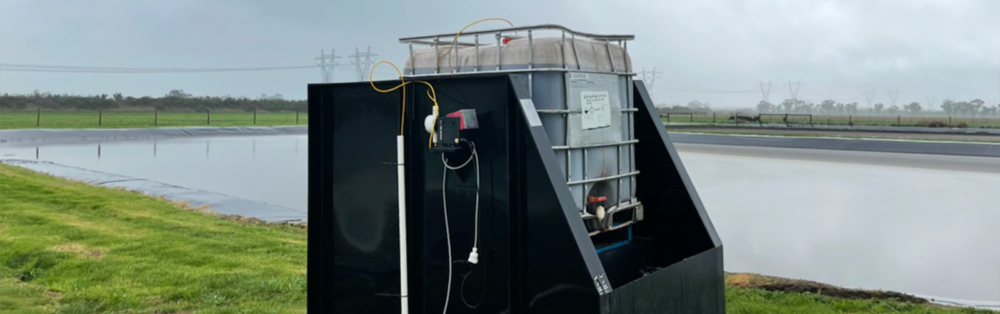

A mining client was required to temporarily release to drain 5-10 L/sec of process water to sewer. Ensuring pH was maintained during this period was critical for their release license.

Hydroflux offered a fully maintained pH control system for the temporary project, which added controlled amounts of acids/bases as required to manage the pH level prior to discharge.

A F&B client was required to provide immediate control of H2S release to sewer as part of their release license.

Hydroflux offered a fully maintained automated pumping system to help chemically neutralise the H2S prior to discharge.

A pulp and paper client required an immediate solution to generate over 2000 L/hour of polymer solution ‘to ensure there DAF system produced complaint waste for release to sewer.

Hydroflux offered a fully maintained automated polymer make up system with the capacity to produce up to 3000 L/hr of 1% polymer solution. The system provided minimal footprint and only required access to fresh potable water and access to a standard 10amp GPO.